| Message |

Probable cause |

Suggested actions |

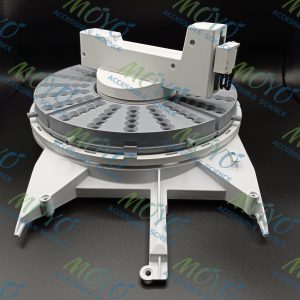

| Bottle in gripper |

- The sample vial was not delivered properly and stayed in the tray gripper.

|

- Remove the vial and return it to its position in the tray.

- Ensure that the tray quadrants are snapped into place.

- Ensure that the injector is plugged into the correct connector on the back of the GC. For 6890, ensure it is configured properly.

- Check the deliver to location for the vial and verify that the location is empty and free from obstructions.

- Make sure that the injector is upright/vertical on the GC.

- Restart the sequence.

- If the error occurs again:

Replace Autosampler Vial Gripper

Replace Autosampler Spring Loaded Belt Tensor

OR

Contact Moyo Scientific Service.

|

| Front (or Back) door open or Injector not mounted |

|

- See “Fault light is on” in Faults

|

| Front (or Back) injector com error |

- There is a communications error between the injector and the GC.

|

|

| Front (or Back) Injector Incomplete Injection |

- The syringe needle is bent.

- The plunger or syringe carriage is operating incorrectly during injection.

|

- See “Correcting Syringe Problems” on page 24 of the user manual.

- Remove the syringe from the injector and check the plunger for stickiness or binding. Replace the syringe if necessary.

- Restart the sequence.

- If the error occurs again,

Replace Injector Needle Assembly.

Replace Injector Needle Support Rod.

OR

Contact Moyo Scientific Service.

|

| Front (Or Back) Injector Reset |

- There is an interruption in the power supply from the GC

|

- Contact Moyo Scientific Support

|

| Front (Or Back) Plunger Error |

- The syringe plunger is sticking, or not securely connected to the plunger carrier.

- The plunger solenoid is binding.

- The plunger carrier encoder is inoperable.

|

- Remove the syringe and check it for plunger stickiness or binding. Replace the syringe if necessary. For more information, see Inspecting a syringe in the Operation Guide.

- Check the viscosity of the sample against the viscosity parameter. Reset the viscosity parameter if necessary.

- Restart the sequence.

- If the error occurs again,

Replace Injector Plunger Motor.

Replace Injector Needle Assembly.

OR

Contact Moyo Scientific Service.

|

| Front (Or Back) Syringe Error |

- The syringe carriage motor is defective.

- The syringe is not currently installed or is an incorrect type.

- The syringe carriage sensor is inoperable.

|

- Ensure the syringe is installed correctly. For more information, see your Operation Guide.

- Ensure the syringe meets specifications.

- If the syringe needle is bent, see Correcting Syringe Problems on page 24 of the user manual.

- Restart the sequence.

- If the error occurs again, contact Moyo Scientific Service

|

| Front (Or Back) Turret Error |

- Something has interfered with the turret rotation.

- The turret motor/encoder assembly is inoperable.

- The turret type was changed while the power was on and the turret alignment procedure was not performed.

- Turret is loose.

|

- Clear any obstructions.

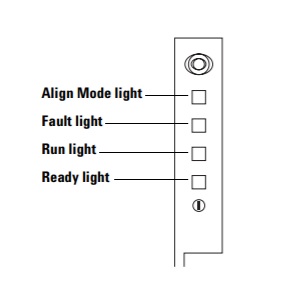

- Check the Align Mode light. If it is lit, perform the alignment procedure (See Turret alignment in the user manual).

- Tighten the knurled nut on the top of the turret.

- If the error occurs again,

Replace Injector Turret.

Replace Injector Turret Motor.

OR

Contact Moyo Scientific Service.

|

| Injector Not Present |

- There is a board failure in the injector or GC.

- The injector cable is bad or not securely connected to the GC.

- There is a cable failure in the GC.

- Your method specifies an incorrect injector location (method mismatch).

|

- Make sure that the injector to GC cable connection is secure.

- Check your method to make sure it uses the appropriate injector location.

- If the error remains,

Replace GC Mainboard.

Replace Injector Rear Board (G2613-60010-M).

OR

Contact Moyo Scientific Service.

|

| Injector Offline |

- There is a board failure in the injector or GC.

- The injector cable is bad or not connected.

- There is a cable failure in the GC.

|

- Make sure that the injector to GC cable connection is secure.

- If the error remains,

Replace GC Mainboard.

Replace GC Injector Rear Board.

OR

Contact Moyo Scientific Service.

|

| No Bar Code Reader |

- Bar code reader cable not securely connected.

- Bar code reader is defective.

- Tray is defective.

|

- Ensure the bar code reader cable connection is secure.

- If the problem continues, Contact Moyo Scientific Service.

|

| No Bottle in Gripper |

- The sample vial was not found by the gripper.

- The gripper could not grasp the vial.

- The vial was dropped during transfer to or from the turret.

- The sensor in the gripper is defective

|

- Make sure that the sample vials are in the locations specified by the sequence.

- Make sure that the sample vials meet recommended specification. See your Sampling Techniques Handbook.

- If you are using adhesive labels, verify that the labels are properly installed. See your Operation Guide.

- If the error recurs frequently,

Replace Autosampler Vial Gripper.

Replace Autosampler Arm Board.

Replace Autosampler Flex Cable.

OR

Contact Moyo Scientific Service.

|

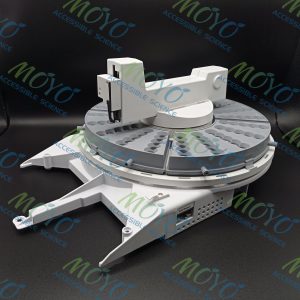

| Tray Not Present |

- There is a board failure in the tray or GC.

- The tray cable is bad or not connected between the GC and tray.

- There is a cable failure in the GC.

|

- Make sure that the tray cable connection is secure.

- Replace the tray cable.

- If the error remains:

Replace GC Mainboard.

OR

Contact Moyo Scientific Service.

|

| Tray Offline |

- There is a board failure in the tray or GC.

- The tray cable is bad or not connected.

- There is a cable failure in the GC

|

- Make sure that the tray to GC cable connection is secure.

- Replace the tray cable.

- If the error remains:

Replace GC Mainboard.

OR

Contact Moyo Scientific Service.

|

| Invalid Sequence |

- The sequence is set up for the wrong injection device.

- Hardware required by the sequence is not installed and configured.

- The GC configuration was changed during sequence execution.

- The injector cable is bad or not connected properly

|

- Make sure that the connection to the GC is secure.

- Verify the sequence parameters against the GC configuration.

- If the error remains, contact Moyo Scientific Service.

|

| No Injector |

- The cabling connection to the GC became loose during a run.

- An injector board or GC board failed during a run.

|

- Make sure that the connection to the GC is secure.

- If the error remains:

Replace GC Mainboard.

Replace Injector Read Board.

OR

Contact Moyo Scientific Service

|

| Prerun > 10 Min |

|

- Check for Not Ready and other GC messages to determine the cause

|

| Sampler Error |

- The sampler could not function for an undocumented reason

|

- Record the code number shown in the Control Module error message.

If the problem persists, Contact Moyo Scientific Service and report the error number

|