Troubleshooting

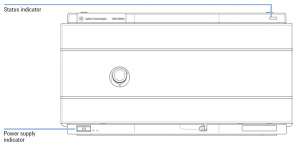

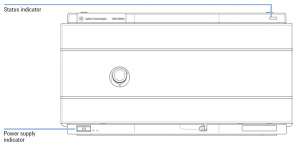

Status:

Two lights indicate the device operational status:

| Lights | Module condition | Explanation |

| Status light OFF and power supply light ON | Prerun mode | Module ready to begin an analysis. |

| Green status light | Run mode | Module performing an analysis. |

| Yellow status light | No-ready mode | Module waiting for a specific condition to be reached or completed. |

| Red status light | Error mode | An error has occurred during analysis. See the status display of the user interface to find the cause. |

| Blinking status light | Resident mode | Module is being updated |

| Fast blinking status light | Low-level error mode | Module must be rebooted / cold-started. A firmware update may be needed. If problem persists, replace Main Board or contact Moyo Scientific Service. |

Error messages:

Whenever an error occurs in the system, it will propagate through the CAN bus or APG remote cable. Depending on whether it occurred during a method run or not, the other modules will be informed and stopped, or will remain idle waiting for the system to be ready again.

General errors

The following is a list of errors regarding all HPLC modules:

| Message | Probable causes | Suggested actions |

| 0062 – Timeout |

|

|

| 0063 – Shutdown |

|

|

| 0070 – Remote Timeout |

|

|

| 0071 – Lost CAN Partner |

|

|

| 0064 – Leak |

|

|

| 0083 – Leak sensor open |

|

Contact Moyo Scientific Service. |

| 0082 – Leak sensor short |

|

Contact Moyo Scientific Service. |

| 0081 – Compensation sensor open | Defective Main Board | Contact Moyo Scientific Service. |

| 0080 – Compensation sensor short | Defective Main Board | Contact Moyo Scientific Service. |

| 0068 – Fan failed |

|

Contact Moyo Scientific Service. |

| 0205 – Open cover |

|

|

| Cover violation |

|

|

Pump related errors

The following is a list of pump specific errors:

| Message | Probable causes | Suggested actions |

| 2055 / 2524 – Solvent zero counter |

|

|

| 2014 / 2500 – Pressure above upper limit |

|

|

| 2015 / 2501 – Pressure below lower limit |

|

|

| 2016 – Pressure signal missing |

|

Contact Moyo Scientific Service. |

| 2054 – Missing pressure reading |

|

Contact Moyo Scientific Service. |

| 2060 – Wrong pump configuration | Gradient valve disconnected. | Reconnect the gradient valve. |

| 2043 – MCGV fuse Valve Fuse 0: Channels A and B Valve Fuse 1: Channels C and D |

|

|

| 2044 – AIV fuse |

|

|

| 2040 – Valve failed (MCGV) Valve 0 Failed: valve A Valve 1 Failed: valve B Valve 2 Failed: valve C Valve 3 Failed: valve D |

|

|

| 2041 / 2042 – Motor-drive power |

|

|

| 2048 / 2052 – Inlet-vale missing |

|

|

| 2517 – Temperature out of range | Defective main board. | Contact Moyo Scientific Service |

| 2517 – Temperature limit Exceeded |

|

|

| 2201 / 2211 – Servo restart failed |

|

|

| 2202 / 2212 – Pump head missing |

|

|

| 2203 / 2213 – Index limit |

|

|

| 2204 / 2214 – Index adjustment |

|

|

| 2205 / 2215 / 2505 – Index missing |

|

Contact Moyo Scientific Service. |

| 2206 / 2216 – Stroke length | Defective pump drive assembly. | Contact Moyo Scientific Service. |

| 2207 / 2217 – Initialisation failed |

|

|

| 2053 – Wait timeout |

|

|

| 2243 – Degasser: signal fail Parameters:

|

|

Contact Moyo Scientific Service |

| 2244 – Degasser: limit not reached |

|

Contact Moyo Scientific Service |